1. SO₂ concentration in flue gas outlet is less than 35mg/m³;

2. Leak ammonia concentration in exhaust is less than 20mg/m³;

3. Water content in exhaust is relatively high, around 10-20%.

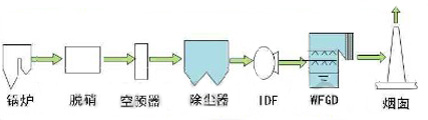

1.In order to reduce NOx emission to meet local exhaust control standard, there will be over-dosed ammonia leaked during SNCR and SCR procedure, althrough subsequent FGD/WESP procedures can absorb partial ammonia, but there is still lower concentration NH3 go into atmosphere;

2.Condensed water, leaked ammonia and SO₂ will react together to ammonia salt, which can absorb SO₂ and lead to lower or 0 SO₂ reading;

3.Due to FGD and WESP procedures humidify flue gas and reduce temp. of flue gas, water concentration is very high around 10-20%. If there is no GGH, exhaust temp. is lower around 45-55C.

1.CEMS T90 response time is far more than 200s for SO₂ whole CEMS calibration, which can’t meet the requirements of 6.2.1.2 in the national standard HJ76-2017;

2.CEMS indication error is far more than ±2.5% for SO₂ whole CEMS calibration, which can’t meet the requirements of 6.2.1.3 in the national standard HJ76-2017;

3.There are condensed water and ammonia salt deposit in the pipeline of CEMS, which block the pipeline and lead to frequent maintenance of the system.

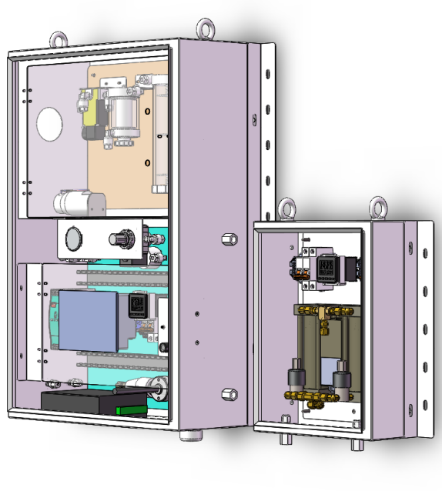

Recommend PreGASS-9600 precondition systems to handle ammonia salt and condensed water problems, retain target acid gases, in order to guarantee precision of monitoring system, and keep CEMS operated in a long-term, stable and reliable way, and realize the real reaction of procedure actual operation.

PreGASS-9600 preconditioning system

1.AlwaysBrong provides professional on-site survey service to fully understand the actual operation and problems of on-site CEMS;

2.Evaluate based on specific conditions and problems onsite, and put forward professional tailor-made solutions;

3.Complete on-site installation and commissioning, ensure the correct implementation of the solution and achieve the corresponding performance;

4.Continuously track the operation of the system to ensure that the problems have been solved and meet the expectations of the solution.